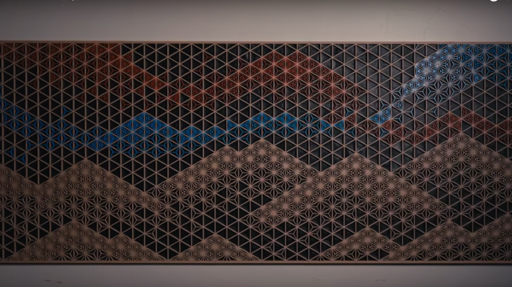

Careful Design Lets 3D Print Emulate Kumiko | Hackaday

-

This post did not contain any content.

-

This post did not contain any content.

So that video alone looks like it costs around $2700 to produce. The amount of work effort in this looks only slightly less than making an actual woodwork piece but the end result will still have a Legoy look up close.

I absolutely applaud the work here, but the effort spent to end result does not equate to value for the large piece in my personal view. I'd rather pick up some extra shifts and purchase a $2700 piece of master crafted wood art than attempt this. -

So that video alone looks like it costs around $2700 to produce. The amount of work effort in this looks only slightly less than making an actual woodwork piece but the end result will still have a Legoy look up close.

I absolutely applaud the work here, but the effort spent to end result does not equate to value for the large piece in my personal view. I'd rather pick up some extra shifts and purchase a $2700 piece of master crafted wood art than attempt this.Fun design exercise though.

-

So that video alone looks like it costs around $2700 to produce. The amount of work effort in this looks only slightly less than making an actual woodwork piece but the end result will still have a Legoy look up close.

I absolutely applaud the work here, but the effort spent to end result does not equate to value for the large piece in my personal view. I'd rather pick up some extra shifts and purchase a $2700 piece of master crafted wood art than attempt this.5kg for 1.125^2^ square meters. About 50mm high/thick. $105 filament cost. Could be much less filament/print time with "speed holes" in depth. He also uses very dense "hexagon fill patterns". He put in an extra step to cover seams so it would not look lego-ey. Many alternate section joining techniques including raised front and back strips, and center patterns that lock sections without locking to each other.

https://kumikowoodworking.com/design/ has this pattern: https://kumikowoodworking.com/products/tn-114/

which is a strip design, and center sections could use a "center joint" with center patterns recessed from "strucutral stips"

There is a guitar made from wood process that requires a lot of woodworking gear and much more assembling/fine tuning time, so this would be easier.